A Report by the Scottish Food Enforcement Liaison Committee’s

Research Working Group:- 2009 local authority food testing report.

Monday, October 11, 2010

National Britannia BRC Suspension

BRC Suspension of NB Certification

The BRC formally suspended BRC recognition of NB Certification (also known as

National Britannia) from auditing against all BRC Global Standard certification

schemes on the 24th September 2010.

The Accreditation of NB Certification has also been suspended by their Accreditation

Body UKAS.

The BRC Compliance Manager Karen Betts will be working closely with NB

Certification to review certification processes and ensure that appropriate additional

safeguards have been put in place to ensure the integrity of the BRC scheme.

It is anticipated that a further audit will be undertaken by UKAS in early November to

review the corrective action put in place and establish if the suspension can be lifted.

The swift action taken by the BRC underlines the importance which is placed on the

absolute integrity of the BRC scheme and emphasises the value of complaints and

feed back from users of the schemes in support of our compliance activities.

Consequences of this action:-

Sites with audits pending

NB Certification are not permitted to undertake BRC audits whilst suspended.

Sites with audits currently planned during the suspension period will be contacted by

NB Certification. NB Certification will undertake to work closely with such clients and

to offer to them as an option the provision of accredited audit services using another

BRC recognised accredited certification body. Dispensation will be allowed for a delay

of up to 28 days in the audit dates to accommodate this process.

Audited sites who have not yet been issued with a certificate

NB Certification are not permitted to issue accredited certificates whilst suspended.

This will result in a delay in the issue of certificates whilst suspension remains in

place. Once suspension is lifted sites within the certification process may then be

issued with an accredited certificate. The BRC have made major retailers aware of

the potential for delay in certification. Sites may choose to restart the certification

process with another BRC recognised and accredited certification body if they so wish.

Existing certificated sites

A review has been undertaken of the processes operated by NB Certification to

ensure the validity of currently issued certificates. At this stage there is no reason to

doubt the validity of these certificates and the certificates will be valid for the

duration of the certificate.

When will suspension be lifted ?

The suspension can only be lifted once corrective actions have been put in place and

BRC and UKAS are satisfied that certification processes are again operating

satisfactorily. An audit is scheduled for the beginning of November which will

establish if suspension can be lifted.

For further information contact

NB Certification

+ 44 2920 856509

certification@nbcert.com

Karen Betts

Compliance Manager

Tel 020 78548935

The BRC formally suspended BRC recognition of NB Certification (also known as

National Britannia) from auditing against all BRC Global Standard certification

schemes on the 24th September 2010.

The Accreditation of NB Certification has also been suspended by their Accreditation

Body UKAS.

The BRC Compliance Manager Karen Betts will be working closely with NB

Certification to review certification processes and ensure that appropriate additional

safeguards have been put in place to ensure the integrity of the BRC scheme.

It is anticipated that a further audit will be undertaken by UKAS in early November to

review the corrective action put in place and establish if the suspension can be lifted.

The swift action taken by the BRC underlines the importance which is placed on the

absolute integrity of the BRC scheme and emphasises the value of complaints and

feed back from users of the schemes in support of our compliance activities.

Consequences of this action:-

Sites with audits pending

NB Certification are not permitted to undertake BRC audits whilst suspended.

Sites with audits currently planned during the suspension period will be contacted by

NB Certification. NB Certification will undertake to work closely with such clients and

to offer to them as an option the provision of accredited audit services using another

BRC recognised accredited certification body. Dispensation will be allowed for a delay

of up to 28 days in the audit dates to accommodate this process.

Audited sites who have not yet been issued with a certificate

NB Certification are not permitted to issue accredited certificates whilst suspended.

This will result in a delay in the issue of certificates whilst suspension remains in

place. Once suspension is lifted sites within the certification process may then be

issued with an accredited certificate. The BRC have made major retailers aware of

the potential for delay in certification. Sites may choose to restart the certification

process with another BRC recognised and accredited certification body if they so wish.

Existing certificated sites

A review has been undertaken of the processes operated by NB Certification to

ensure the validity of currently issued certificates. At this stage there is no reason to

doubt the validity of these certificates and the certificates will be valid for the

duration of the certificate.

When will suspension be lifted ?

The suspension can only be lifted once corrective actions have been put in place and

BRC and UKAS are satisfied that certification processes are again operating

satisfactorily. An audit is scheduled for the beginning of November which will

establish if suspension can be lifted.

For further information contact

NB Certification

+ 44 2920 856509

certification@nbcert.com

Karen Betts

Compliance Manager

Tel 020 78548935

Wednesday, September 01, 2010

Food Standards Agency Guidance (219 guidance documents)

The following link gives you direct access to 219 guidance documents published by the Food Standards Agency:-

http://www.food.gov.uk/multimedia/pdfs/fsapublishedguidancemar10.pdf

http://www.food.gov.uk/multimedia/pdfs/fsapublishedguidancemar10.pdf

Tuesday, August 31, 2010

HACCP Validation Resources

The National Advisory Committee on Microbiological Criteria for Foods (NACMCF):-

http://www.fsis.usda.gov/About_FSIS/NACMCF/index.asp

Advisory Committee on the Microbiological Safety of Food (ACMSF):- http://acmsf.food.gov.uk/

The Codex Alimentarius Commission was created in 1963 by FAO and WHO to develop food standards, guidelines and related texts such as codes of practice under the Joint FAO/WHO Food Standards Programme. The main purposes of this Programme are protecting health of the consumers and ensuring fair trade practices in the food trade, and promoting coordination of all food standards work undertaken by international governmental and non-governmental organizations.:- http://www.codexalimentarius.net/search/advancedsearch.do

http://ec.europa.eu/food/index_en.htm

http://www.food.gov.uk/aboutus/contactus/

http://www.chilledfood.org/Resources/Chilled%20Food%20Association/Public%20Resources/ECFF20Recommendations20Final201820122006.pdf

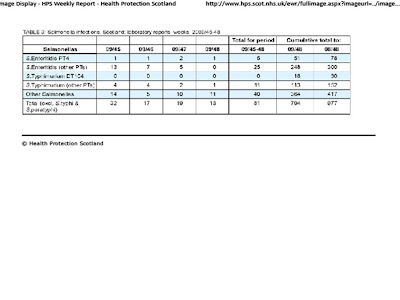

Health Protection Scotland

http://www.google.com/reader/view/feed/http%3A%2F%2Fwww.hps.scot.nhs.uk%2Fusingourwebsite%2FFeeds%2FGastroCurrentNews.aspx

Bad Bugs Book

http://www.fda.gov/Food/FoodSafety/FoodborneIllness/FoodborneIllnessFoodbornePathogensNaturalToxins/BadBugBook/default.htm

Outsource Solution News

http://www.outsourcesolution.co.uk/news.php

Outsource Solution RSS blogger link

http://www.google.co.uk/reader/shared/03986148134012621369

http://www.fsis.usda.gov/About_FSIS/NACMCF/index.asp

Advisory Committee on the Microbiological Safety of Food (ACMSF):- http://acmsf.food.gov.uk/

The Codex Alimentarius Commission was created in 1963 by FAO and WHO to develop food standards, guidelines and related texts such as codes of practice under the Joint FAO/WHO Food Standards Programme. The main purposes of this Programme are protecting health of the consumers and ensuring fair trade practices in the food trade, and promoting coordination of all food standards work undertaken by international governmental and non-governmental organizations.:- http://www.codexalimentarius.net/search/advancedsearch.do

http://ec.europa.eu/food/index_en.htm

http://www.food.gov.uk/aboutus/contactus/

http://www.chilledfood.org/Resources/Chilled%20Food%20Association/Public%20Resources/ECFF20Recommendations20Final201820122006.pdf

Health Protection Scotland

http://www.google.com/reader/view/feed/http%3A%2F%2Fwww.hps.scot.nhs.uk%2Fusingourwebsite%2FFeeds%2FGastroCurrentNews.aspx

Bad Bugs Book

http://www.fda.gov/Food/FoodSafety/FoodborneIllness/FoodborneIllnessFoodbornePathogensNaturalToxins/BadBugBook/default.htm

Outsource Solution News

http://www.outsourcesolution.co.uk/news.php

Outsource Solution RSS blogger link

http://www.google.co.uk/reader/shared/03986148134012621369

Clostridium estertheticum

Spoilage of beef, lamb and venison by psychrophilic and psychrotrophic clostridial species renders meat unacceptable resulting in financial losses and reduced consumer confidence. A number of clostridial strains, including Clostridium algidicarnis, Clostridium algidixylanolyticum, Clostridium estertheticum, Clostridium frigidicarnis and Clostridium gasigenes, have been implicated in red meat spoilage. Unlike other spoilers, these clostridia are able to grow in anaerobic conditions and at chilled temperatures (some at −1.5 °C the optimal storage temperature for chilled red meat). The spoilage they cause is characterised by softening of the meat, production of large amounts of drip (exudates), offensive odours and in the case of C. estertheticum and C. gasigenes production of gas. Spoilage occurs following the introduction of clostridial spores into vacuum packages during processing. Germination of spores is necessary for the growth of vegetative cells, which cause spoilage. Current mitigation strategies focus on good management practice within meat processing plants. However, this is not always sufficient to prevent spoilage.

Monday, August 30, 2010

2010 infections in Scotland

Viral and protozoal pathogens up to Week 32, 2010

Norovirus

During the first 32 weeks of 2010, 2654 reports of norovirus (NV) were received at HPS, an increase of 1632 (160%) compared to the same period in 2009 when there were 1022 reports. This large increase is due to the large number of reports in the first 12 weeks of the year.

During the first half of 2010, 274 general outbreaks of NV were reported to ObSurv, the surveillance system for all general outbreaks of infectious intestinal disease in Scotland. This is an increase of 108 (65%) compared to the first half of 2009 when 166 NV outbreaks were reported. It is however similar to the first half of 2008 during which 249 NV outbreaks were reported. Residential institutions and hospitals have been the two main locations identified in NV outbreaks in 2010, accounting for 50% and 46% of NV outbreaks respectively.

Rotavirus

During the first 32 weeks of 2010, 1684 reports of rotavirus were received at HPS, an increase of 406 (32%) compared to the same period in 2009 when there were 1278 rotavirus reports. The number of reports in 2010 is similar to 2008 when there were 1710 reports.

To date in 2010 there have been no outbreaks of rotavirus reported to ObSurv, the last such outbreak was reported in 2007.

Increased reporting of E. coli O157 infections in 2010

During the first 32 weeks of 2010, HPS received 146 reports of E. coli O157 infections, an increase of 29 (25%) from the same period of 2009. A number of factors may have contributed to this increase.

The number and proportion of secondary and asymptomatic infections, for instance, has increased substantially. In weeks 1-32 of 2010, 26 cases (18%) were secondaries and 14 (10%) were asymptomatic, compared with 15 (13%) secondaries and 2 (2%) asymptomatic in the same period of 2009.

Norovirus

During the first 32 weeks of 2010, 2654 reports of norovirus (NV) were received at HPS, an increase of 1632 (160%) compared to the same period in 2009 when there were 1022 reports. This large increase is due to the large number of reports in the first 12 weeks of the year.

During the first half of 2010, 274 general outbreaks of NV were reported to ObSurv, the surveillance system for all general outbreaks of infectious intestinal disease in Scotland. This is an increase of 108 (65%) compared to the first half of 2009 when 166 NV outbreaks were reported. It is however similar to the first half of 2008 during which 249 NV outbreaks were reported. Residential institutions and hospitals have been the two main locations identified in NV outbreaks in 2010, accounting for 50% and 46% of NV outbreaks respectively.

Rotavirus

During the first 32 weeks of 2010, 1684 reports of rotavirus were received at HPS, an increase of 406 (32%) compared to the same period in 2009 when there were 1278 rotavirus reports. The number of reports in 2010 is similar to 2008 when there were 1710 reports.

To date in 2010 there have been no outbreaks of rotavirus reported to ObSurv, the last such outbreak was reported in 2007.

Increased reporting of E. coli O157 infections in 2010

During the first 32 weeks of 2010, HPS received 146 reports of E. coli O157 infections, an increase of 29 (25%) from the same period of 2009. A number of factors may have contributed to this increase.

The number and proportion of secondary and asymptomatic infections, for instance, has increased substantially. In weeks 1-32 of 2010, 26 cases (18%) were secondaries and 14 (10%) were asymptomatic, compared with 15 (13%) secondaries and 2 (2%) asymptomatic in the same period of 2009.

Sunday, July 25, 2010

Carnoustie Team is 'Top of the class'

Co-Operative Farms Carnoustie Team is ‘Top of the Class’

By Bill Longair

Congratulations must go to four of Carnoustie’s team who have recently sat the intermediate level 3 HACCP course with all four candidates achieving distinction level.

This sees our sites ongoing commitment to build a robust internal audit team able to independently meet the challenges of supply into the fresh produce industry.

As Operations Manger I am delighted to quote Mr. Duncan Perry from Outsource Solutions who stated, ‘The first time in which we have ever run a course in which 100% candidates have all achieving ‘distinction’. ‘It is exceptional that a single operational site has achieved this level of competence’.

My personal congratulations goes to Liz Veitch who heads the Quality control side of the operation and this result is a credit to her, her team and the site.

Well done to you all

Pictured from left to right, Liz Veitch, Gillian Craig, Douglas Charlton, Sandra Kizuk and Duncan Perry (Outsource Solutions).

Wednesday, June 30, 2010

Wednesday, June 23, 2010

EXECUTIVE SUMMARY

Since its development in the late 1950’s HACCP has become an internationally recognised tool to help business operators attain a higher standard of food safety. In this time, it has gone from being a recommendation of good practice to being enshrined in legislation. The purpose of HACCP is to ensure a high level of consumer protection with regard to food safety throughout the entire food chain. The HACCP system, according to Codex Alimentarius Commission 2003 (Codex), ISBN 92-5-105106-2, is science based and systematic. The use of HACCP as a tool enables the assessment of specific hazards and measures for their control to ensure the safety of food. It also puts the focus and emphasis on prevention rather than relying on end-product testing.

Hazard Analysis and Critical Control Point system - HACCP

HACCP was initially developed by The Pillsbury Company for NASA and its manned space programme back in 1959. It was based on the engineering system Failure, Mode, Effect and Analysis (FMEA) and designed as an alternative to end-product testing as a means of ensuring the safety of food. In order to establish what is a potential hazard the questions; what could go wrong and why, must be considered. The possible outcome and likelihood of occurrence are considered at each stage in the process to produce food fit for consumption by consumers.

HACCP is a systematic approach that is applied throughout the entire food chain, range of applications. The application of a HACCP approach was made mandatory in the European Union by EC regulation 852/2004 in Article 5. This article states that food business operators shall put in place, implement and maintain a permanent procedure or procedures based on the HACCP principles.

Successful implementation requires the full cooperation and commitment of food business employees at all levels along with relevant training at all levels. Training requirements should be considered prior to the implementation of a HACCP system. In addition, business operators must provide the competent authority with evidence of compliance and training. This can be achieved by using a training programme accredited by a body such as Royal Society for Public Health (RSPH).

Protection of public health

A European Community White Paper on food safety published in January 2000 stated that “The production and consumption of food is central to any society, and has economic, social and, in many cases, environmental consequences.” It also emphasised that health protection must always take priority over all other issues and that every link along the food chain, from farm to fork must be as strong as the others if consumers are to be adequately protected. The paper acknowledged the need to re-establish confidence in the safety of food supply following a number of crises within the food supply chain during the 1990’s. Bovine Spongiform Encephalitis (BSE) and antibiotic use (for growth promotion) and subsequent resistance issues were just a few of the problems during the 1990’s.

There were also several outbreaks of foodborne illness, such as the Eschericia coli outbreak of 19962 and others throughout the 1990’s some of which proved fatal for a number of vulnerable people. As stated by the World Health Organisation’s Codex Alimentarius Committee, (Codex), “people have the right to expect the food they eat to be safe and suitable for consumption”.

In 2003 Codex recommended a HACCP-based approach as a means to enhance food safety. On 1st January 2006 Regulation (EC) No 852/2004 became effective. Food businesses in the UN are now required by law to implement a food safety management system based on Codex HACCP principles.

HACCP in Action

From the 1st of January 2006, when Regulation (EC) No 852/2004 came into effect, HACCP (or a food safety management system based on HACCP principles) was no longer optional for many food businesses, but became mandatory. It is the responsibility of businesses to comply with the regulation and the responsibility of local authorities to inspect and enforce it.

There are many benefits to businesses using HACCP as a tool, among them are a reduced likelihood of food poisoning outbreaks, a reduction in customer complaints, standardised training and more importantly compliance with legislation. Evidence of a live HACCP system and proof of food safety compliance is often a pre-requisite to trading with some suppliers.

A properly documented HACCP system offers inspectors evidence that essential process conditions were under control throughout processing, making inspections easier.

Before HACCP can be implemented within a process there are various steps, or pre-requisites, that need to be in place. One of these pre-requisites is training. To successfully implement HACCP training is required for HACCP team members and senior management. Training of senior management is crucial to ensure awareness and commitment to HACCP throughout. Clearly not everybody requires the same training and making sure that training is specific to employee level and operational status is an important factor for consideration as is the quality of the training given.

There are many HACCP training providers but one that is suitably accredited must be selected to ensure integrity of the HACCP system to which the training will be applied. Codex states that “Those engaged in food operations who come directly or indirectly into contact with food should be trained, and/or instructed in food hygiene to a level appropriate to the operations they are to perform”, and acknowledges that training is fundamentally important to any food hygiene system, with inadequate training of all personnel being a potential threat to the safety of food.

Training programmes should be routinely reviewed in order to ensure they take into account any changes in legislation, technology, processing procedures or emerging pathogens.

Development Timeline

YEAR PROGRESS/STEP

1950’s /60’s The engineering system of Failure Mode and Effect Analysis (FMEA) was adapted to form the beginnings of the HACCP system.

1970’s HACCP presented to public at a food protection conference which led to a number of large food manufacturers starting to use the HACCP approach. (Not required by regulators nor promoted internationally at this stage.)

1980’s Greater uptake of HACCP approach due to the recommendation by US National Academy of Science and the International Commission for Microbiological Criteria for Foods.

1994

1995 Full international acceptance of HACCP with the World Health Organisation’s Codex Alimentarius Committee on food hygiene, publishing HACCP principles.

EC Directive on the Hygiene of Foodstuffs (93/43) implemented through the Food Safety Regulations 1995.

2006/08 Commission of the European Communities publishes a white paper on food safety proposing a new approach driven by the need to guarantee a high level of food safety.

European Commission Decision 2001/471/EC requires the application of HACCP principles in licensed fresh meat & poultry meat plants and lays down certain microbiological test procedures. Member states are required to implement the decision by 7th June 2002.

European Food Safety Authority established through Regulation 178/2002. Voluntary Codes of Practice introduce a requirement for HACCP systems within the feed industry part of the food chain.

Feed Additive Regulation (1831/2003).

Food Hygiene Regulation (852/2004) All businesses shall put in place, implement and maintain permanent procedures based on HACCP principles.

Food Hygiene Scotland Regulation 2006

Feed Hygiene Regulation (183/2005) HACCP systems must be registered/approved for all except primary producers (farmers). Personnel must be trained in hygiene issues and HACCP.

Feed businesses must register with local authorities and must develop and implement HACCP systems within their operation.

This decade saw the beginnings of encompassing the entire food chain from farm to fork with regulation on the feed being fed to animals which were intended for human consumption.

2010 In accordance with Regulation (EC) 853/2004, from January 1st 2010 Food Chain Information (FCI) is required for all Cattle, Sheep and Goats submitted for slaughter for human consumption. (Required for Poultry 2006, Pigs 2008 and Calves and Horses 2009)

The above list is not an exhaustive list of legislation pertaining to food and feed businesses, passed to date.

Conclusion

Successful application of HACCP requires the full commitment and involvement of management and the workforce. The international standard ISO 22000 requires that management provide evidence of its ongoing commitment to a food safety management system. The efficacy of any HACCP system is reliant on management and employees having the appropriate HACCP knowledge and skills1, therefore ongoing training is essential for all levels of employees. It is the responsibility of each individual business to ensure they have robust HACCP processes in place which are fully documented. Constant changes in processing technology, emerging pathogens and staff turnover necessitate continuous review of HACCP procedures and training requirements.

Attention should be given to the quality of training provided which should ideally be accredited by a body such as the Royal Society for Public Health (RSPH). Such accreditation allows a company to demonstrate that staff have undertaken training which meets appropriate standards to ensure highest level of food safety.

Since its development in the late 1950’s HACCP has become an internationally recognised tool to help business operators attain a higher standard of food safety. In this time, it has gone from being a recommendation of good practice to being enshrined in legislation. The purpose of HACCP is to ensure a high level of consumer protection with regard to food safety throughout the entire food chain. The HACCP system, according to Codex Alimentarius Commission 2003 (Codex), ISBN 92-5-105106-2, is science based and systematic. The use of HACCP as a tool enables the assessment of specific hazards and measures for their control to ensure the safety of food. It also puts the focus and emphasis on prevention rather than relying on end-product testing.

Hazard Analysis and Critical Control Point system - HACCP

HACCP was initially developed by The Pillsbury Company for NASA and its manned space programme back in 1959. It was based on the engineering system Failure, Mode, Effect and Analysis (FMEA) and designed as an alternative to end-product testing as a means of ensuring the safety of food. In order to establish what is a potential hazard the questions; what could go wrong and why, must be considered. The possible outcome and likelihood of occurrence are considered at each stage in the process to produce food fit for consumption by consumers.

HACCP is a systematic approach that is applied throughout the entire food chain, range of applications. The application of a HACCP approach was made mandatory in the European Union by EC regulation 852/2004 in Article 5. This article states that food business operators shall put in place, implement and maintain a permanent procedure or procedures based on the HACCP principles.

Successful implementation requires the full cooperation and commitment of food business employees at all levels along with relevant training at all levels. Training requirements should be considered prior to the implementation of a HACCP system. In addition, business operators must provide the competent authority with evidence of compliance and training. This can be achieved by using a training programme accredited by a body such as Royal Society for Public Health (RSPH).

Protection of public health

A European Community White Paper on food safety published in January 2000 stated that “The production and consumption of food is central to any society, and has economic, social and, in many cases, environmental consequences.” It also emphasised that health protection must always take priority over all other issues and that every link along the food chain, from farm to fork must be as strong as the others if consumers are to be adequately protected. The paper acknowledged the need to re-establish confidence in the safety of food supply following a number of crises within the food supply chain during the 1990’s. Bovine Spongiform Encephalitis (BSE) and antibiotic use (for growth promotion) and subsequent resistance issues were just a few of the problems during the 1990’s.

There were also several outbreaks of foodborne illness, such as the Eschericia coli outbreak of 19962 and others throughout the 1990’s some of which proved fatal for a number of vulnerable people. As stated by the World Health Organisation’s Codex Alimentarius Committee, (Codex), “people have the right to expect the food they eat to be safe and suitable for consumption”.

In 2003 Codex recommended a HACCP-based approach as a means to enhance food safety. On 1st January 2006 Regulation (EC) No 852/2004 became effective. Food businesses in the UN are now required by law to implement a food safety management system based on Codex HACCP principles.

HACCP in Action

From the 1st of January 2006, when Regulation (EC) No 852/2004 came into effect, HACCP (or a food safety management system based on HACCP principles) was no longer optional for many food businesses, but became mandatory. It is the responsibility of businesses to comply with the regulation and the responsibility of local authorities to inspect and enforce it.

There are many benefits to businesses using HACCP as a tool, among them are a reduced likelihood of food poisoning outbreaks, a reduction in customer complaints, standardised training and more importantly compliance with legislation. Evidence of a live HACCP system and proof of food safety compliance is often a pre-requisite to trading with some suppliers.

A properly documented HACCP system offers inspectors evidence that essential process conditions were under control throughout processing, making inspections easier.

Before HACCP can be implemented within a process there are various steps, or pre-requisites, that need to be in place. One of these pre-requisites is training. To successfully implement HACCP training is required for HACCP team members and senior management. Training of senior management is crucial to ensure awareness and commitment to HACCP throughout. Clearly not everybody requires the same training and making sure that training is specific to employee level and operational status is an important factor for consideration as is the quality of the training given.

There are many HACCP training providers but one that is suitably accredited must be selected to ensure integrity of the HACCP system to which the training will be applied. Codex states that “Those engaged in food operations who come directly or indirectly into contact with food should be trained, and/or instructed in food hygiene to a level appropriate to the operations they are to perform”, and acknowledges that training is fundamentally important to any food hygiene system, with inadequate training of all personnel being a potential threat to the safety of food.

Training programmes should be routinely reviewed in order to ensure they take into account any changes in legislation, technology, processing procedures or emerging pathogens.

Development Timeline

YEAR PROGRESS/STEP

1950’s /60’s The engineering system of Failure Mode and Effect Analysis (FMEA) was adapted to form the beginnings of the HACCP system.

1970’s HACCP presented to public at a food protection conference which led to a number of large food manufacturers starting to use the HACCP approach. (Not required by regulators nor promoted internationally at this stage.)

1980’s Greater uptake of HACCP approach due to the recommendation by US National Academy of Science and the International Commission for Microbiological Criteria for Foods.

1994

1995 Full international acceptance of HACCP with the World Health Organisation’s Codex Alimentarius Committee on food hygiene, publishing HACCP principles.

EC Directive on the Hygiene of Foodstuffs (93/43) implemented through the Food Safety Regulations 1995.

2006/08 Commission of the European Communities publishes a white paper on food safety proposing a new approach driven by the need to guarantee a high level of food safety.

European Commission Decision 2001/471/EC requires the application of HACCP principles in licensed fresh meat & poultry meat plants and lays down certain microbiological test procedures. Member states are required to implement the decision by 7th June 2002.

European Food Safety Authority established through Regulation 178/2002. Voluntary Codes of Practice introduce a requirement for HACCP systems within the feed industry part of the food chain.

Feed Additive Regulation (1831/2003).

Food Hygiene Regulation (852/2004) All businesses shall put in place, implement and maintain permanent procedures based on HACCP principles.

Food Hygiene Scotland Regulation 2006

Feed Hygiene Regulation (183/2005) HACCP systems must be registered/approved for all except primary producers (farmers). Personnel must be trained in hygiene issues and HACCP.

Feed businesses must register with local authorities and must develop and implement HACCP systems within their operation.

This decade saw the beginnings of encompassing the entire food chain from farm to fork with regulation on the feed being fed to animals which were intended for human consumption.

2010 In accordance with Regulation (EC) 853/2004, from January 1st 2010 Food Chain Information (FCI) is required for all Cattle, Sheep and Goats submitted for slaughter for human consumption. (Required for Poultry 2006, Pigs 2008 and Calves and Horses 2009)

The above list is not an exhaustive list of legislation pertaining to food and feed businesses, passed to date.

Conclusion

Successful application of HACCP requires the full commitment and involvement of management and the workforce. The international standard ISO 22000 requires that management provide evidence of its ongoing commitment to a food safety management system. The efficacy of any HACCP system is reliant on management and employees having the appropriate HACCP knowledge and skills1, therefore ongoing training is essential for all levels of employees. It is the responsibility of each individual business to ensure they have robust HACCP processes in place which are fully documented. Constant changes in processing technology, emerging pathogens and staff turnover necessitate continuous review of HACCP procedures and training requirements.

Attention should be given to the quality of training provided which should ideally be accredited by a body such as the Royal Society for Public Health (RSPH). Such accreditation allows a company to demonstrate that staff have undertaken training which meets appropriate standards to ensure highest level of food safety.

Tuesday, June 15, 2010

HACCP level 3 Training

The next HACCP level 3 course has been set for the 8th and 9th July.

The course is certificated by RSPH and includes course book and materials. There is a 90 minute exam at the end of the second day.

There is an emphasis on practical implementation and this is enhanced by plenty of workshop exercises.

As a training centre we curently have an over 50% distinction pass level.

If you would like to book a place on the next course email us on perry@outsourcesolution.co.uk

For any other training relating to Food Safety or BRC please visit our web site at www.outsourcesolution.co.uk

The course is certificated by RSPH and includes course book and materials. There is a 90 minute exam at the end of the second day.

There is an emphasis on practical implementation and this is enhanced by plenty of workshop exercises.

As a training centre we curently have an over 50% distinction pass level.

If you would like to book a place on the next course email us on perry@outsourcesolution.co.uk

For any other training relating to Food Safety or BRC please visit our web site at www.outsourcesolution.co.uk

Thursday, May 20, 2010

Food Safety Courses

The next Food safety training courses have been scheduled:-

The courses running are

REHIS level 2 HACCP training on the 31st May

RSPH level 3 HACCP training on the 17th and 18th June

For level 3 training we are currently have over 50% delegates achieving a distinction level.

Both of our courses are being run at our training suite at junction 4 of the M8 http://foodsafetyuk.blogspot.com/2010/01/training-suite-directions.html

The level 3 training takes into consideration Codex, BRC requirements and ISO22000

The courses run every 2 -3 months. For up to date information and details of other courses visit our web site at:-

Contact Duncan Perry by email perry@outsourcesolution.co.uk or complete our contact form on http://www.foodtrainingsolution.co.uk/mwebform.asp

Thursday, January 28, 2010

Food Safety Course Spring 2010

The next set of Food Safety Courses have been scheduled for Spring 2010

These are :-

BRC Implementation and Internal Auditing:- 15th February

RSPH Level 3 HACCP Intermediate:- 11th and 12th March

For more information visit http://www.outsourcesolution.co.uk/training.html

or email mailto:perry@outsourcesolution.co.uk

These are :-

BRC Implementation and Internal Auditing:- 15th February

RSPH Level 3 HACCP Intermediate:- 11th and 12th March

For more information visit http://www.outsourcesolution.co.uk/training.html

or email mailto:perry@outsourcesolution.co.uk

Wednesday, January 06, 2010

Tuesday, January 05, 2010

Level 3 HACCP

RSPH Level 3 Award in HACCP for Food Manufacturing

26th and 27th January, Easter Inch, Bathgate

This qualification is primarily aimed at supervisors/junior managers working within the food manufacturing industry, but will also be of benefit to caterers and retailers. Hazard Analysis and Critical Control Point (HACCP) provides an effective and practicable management tool for identifying food safety hazards and ensuring that adequate controls are in place.

This Level 3 qualification covers the importance of HACCP-based food safety management procedures, the preliminary processes for HACCP-based procedures, development of the procedures, monitoring of critical control points and corrective actions and the evaluation of the procedures. Outsource Solution place a particular emphasis on workshop activities to establish a robust understanding of the HACCP implementation process.

Holders of this qualification will have the appropriate knowledge and understanding to be an integral part of a HACCP team and to supervise the implementation of a HACCP-based system in the work environment.

This qualification is based on the National Occupational Standards developed by Improve, the Sector Skills Council, for the Food and Drink Manufacturing Industry and conforms to the qualification template developed by RSPH, other awarding bodies and Improve.

This programme is delivered over two days and assessment is by a 90 minute examination consisting of 45 multiple-choice questions.

26th and 27th January, Easter Inch, Bathgate

This qualification is primarily aimed at supervisors/junior managers working within the food manufacturing industry, but will also be of benefit to caterers and retailers. Hazard Analysis and Critical Control Point (HACCP) provides an effective and practicable management tool for identifying food safety hazards and ensuring that adequate controls are in place.

This Level 3 qualification covers the importance of HACCP-based food safety management procedures, the preliminary processes for HACCP-based procedures, development of the procedures, monitoring of critical control points and corrective actions and the evaluation of the procedures. Outsource Solution place a particular emphasis on workshop activities to establish a robust understanding of the HACCP implementation process.

Holders of this qualification will have the appropriate knowledge and understanding to be an integral part of a HACCP team and to supervise the implementation of a HACCP-based system in the work environment.

This qualification is based on the National Occupational Standards developed by Improve, the Sector Skills Council, for the Food and Drink Manufacturing Industry and conforms to the qualification template developed by RSPH, other awarding bodies and Improve.

This programme is delivered over two days and assessment is by a 90 minute examination consisting of 45 multiple-choice questions.

Monday, January 04, 2010

Training Suite Directions

The easiest route from the M8 is to exit at junction 4. Drive to the second round about and take the 4th exit (as shown on the map in red) A7066.

After 1.9 miles take the first slip road. At the round about take the first exit onto the B792 (Loch View).

Go through the underpass.

At the next round about take the 1st exit.

At the next round about (~200m) take the second exit.

At the next round about (~100m) take the first exit into the Evans Easyspace complex. (The Evans signage is very good)

As you come into the units from the round about bear to your right, we are the far right corner unit at the same side as you have entered (ie the furthest right / south east, closest to the steadings) The unit has its own entrance and signage to the far side of the building .

Subscribe to:

Posts (Atom)